Without a doubt, scheduling is one of the most complex functions within a manufacturing business. For years, the challenge has always been to find a solution that has the complexity to achieve the desired results while still being user friendly.

Let’s pull back the curtain on a feature-rich scheduling tool built with manufacturers in mind.

NetSuite’s Production Scheduling solution is that tool. It gives manufacturers the best of both worlds: its robust features make it possible to create a realistic schedule with minimal effort.

Drag and Drop Scheduling

The task scheduler in NetSuite shows the popular Gantt chart view of production with the ability to manually drag operations for last minute changes.

NetSuite's drag and drop scheduling

Real-Time Scheduling Engine

The NetSuite scheduling engine is unique in that it runs in real-time and can be set to automatically schedule work orders as they are created or reach a defined status. As the work order is saved, each operation will be scheduled according to the defined parameters.

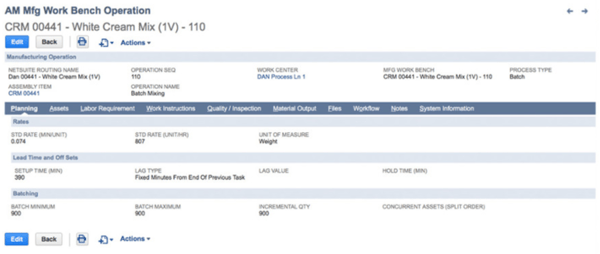

Manufacturing Workbench

NetSuite’s comprehensive workbench functionality provides a single place where most of the configuration is performed. From this one screen you can define:

- Setup and run standards

- Lag and hold time

- Batch configuration

- Asset and labor requirements with priorities

- Detailed work instructions

- Inspection plans with acceptable tolerances

NetSuite's manufacturing workbench

NetSuite's manufacturing workbench

Batch Scheduling

For manufacturers who make their products in batches to match the capacities of their machines (specifically food and beverage manufacturers but broadly applicable), this can easily be attained by defining the appropriate batch parameters.

Once this is done, the system will create and schedule each batch separately to ensure compliance with the capacities of the equipment that’s running them.

Shop Calendar Definition

When finite scheduling is being conducted, the shop calendar defines when a work center is normally available and can be configured with exceptions for lunch, etc. Individual assets (pieces of equipment) can then be setup with variances to this as required.

Work Center Dispatch List

The dispatch list in NetSuite is updated to be color coded based on status and date to provide instant feedback to the Production Manager should there be any issues.

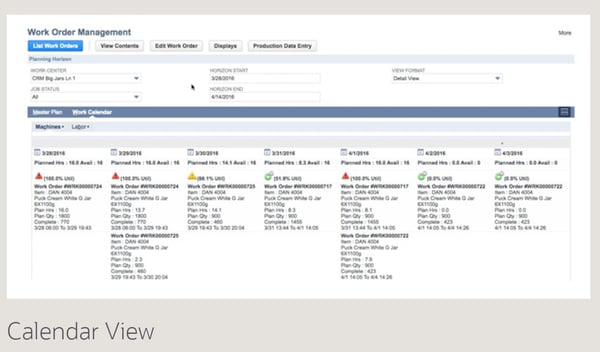

Calendar View

One of the most popular and powerful views of the schedule is the calendar view.

NetSuite's calendar view

This easy-to-read and understand screen shows a traditional calendar with the work orders that are scheduled to be performed in each work center. It also shows additional critical information for use by the scheduler such as:

- Work order status

- Planned and available hours

- Utilization percentage with alerts

- Planned and completed quantity

Real-Time Updates From Production

One of the most important aspects of scheduling is getting the right information back from production to allow for educated decisions about the schedule. This simple list view shows all of the current work orders and automatically highlights potential problem areas.

Key Benefits

To recap, here are the best and brightest features of NetSuite’s Production Scheduling tool for manufacturers:

- Real-time scheduling engine — both forward and backwards

- Flexible scheduling code to enable light to dark sequencing

- Choice of infinite or finite scheduling with user definable constraints

- Multiple graphical representations of the schedule

- Drag-and-drop scheduled operations for manual override

Need Help?

Want to create a realistic manufacturing schedule with minimal effort? Contact us online or give us a call at 410.685.5512 for a demo of NetSuite's Production Scheduling.