Has your manufacturing or distribution business hit a lull due to inventory control challenges? You’re not alone.

I’ve been on the search for a tool that provides a single, real-time view of items, inventory and orders across all selling channels enabling businesses to fulfill orders quickly and accurately.

That’s when I came across NetSuite’s award-winning inventory software, which allows your entire company to operate under one cloud-based integrated solution.

So, what’s so special about this system?

NetSuite streamlines a complex process, making it easier to manage your needs.

With tools for tracking inventory in multiple locations, determining reorder points, managing safety stock and cycle counts, businesses can keep inventory costs low while meeting customer delivery expectations.

Ready to track inventory like a seasoned pro? Let’s look at some common inventory challenges distributors and manufacturers face, and how NetSuite tackles each of them head on.

Common Inventory Challenges and How to Overcome Them

1. Demand-Based Inventory Replenishment

NetSuite provides intelligent control over inventory replenishment, helping ensure that sufficient stock is on hand to fill anticipated orders, while keeping excess stock to a minimum. NetSuite Advanced Inventory enables you to:

- Dynamically manage item reorder points and preferred stock levels based on average lead time, historical or seasonal-based sales demand and number of days’ supply to stock

- Reduce lag time with real-time alerts whenever stock falls to predefined thresholds

- Avoid “stock-outs” to maintain continuity

2. Inventory Control

NetSuite enhances inventory visibility with tracking and control capabilities, across multiple locations, to manage every stage of the lifecycle and control costs. NetSuite Advanced Inventory provides:

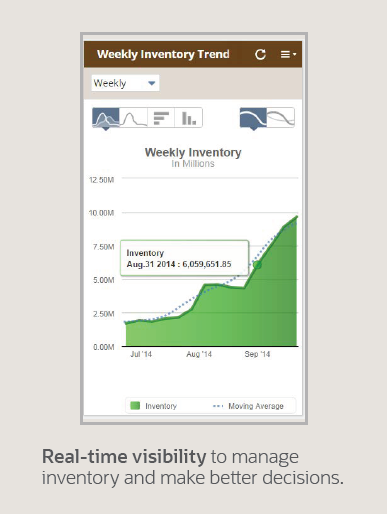

- Real-time visibility of items across all locations and channels

- Matrix item management to stock and sell similar products in various colors, sizes and style combinations and simplify SKU creation and pricing

- Landed cost allocation according to weight, value or quantity

- Serialized inventory to track purchases and sales by assigning a serial number to each item

- Lot management to track the purchase, stock and sale of a group of items by assigning a specific number to the group

- Bin management to organize and track the exact location of items in stock in your warehouse(s)

- Printable bar codes and item labels with transaction numbers on sales orders, packing slips and invoices

- Various forms to run day-to-day supply chain operations, including inventory count sheet, manufacturing dispatch list and manufacturing traveler

- Periodic inventory counts that automatically calculate on-hand item quantities at any time in any location

Inventory Process Management

NetSuite streamlines core processes using automated workflow and simplifies complex tasks by requiring less time and effort. NetSuite Advanced Inventory optimizes operations with:

- Return merchandise authorization where warranty claims can be verified to refund, repair or replace product defects

- Pick, pack and ship management for high-volume order processing environments

Key Benefits

NetSuite delivers what many other ERP systems can’t. I’m all about NetSuite’s Advanced Inventory solution because it:

- Tightens control over your full inventory lifecycle across multiple locations

- Slashes costs for procurement, warehousing, shipping and fulfillment

- Boosts customer satisfaction by eliminating stock-outs and speeding deliveries

- Continuously monitors and improves performance with real-time dashboards and analytics

Need Help?

If you’d like to improve your inventory management and tracking, feel free to contact us online or call 410.685.5512 to see a system like this in action.