Manufacturers and distributors know how critical inventory management is. In fact, manufacturers and distributors who maintain proper inventory levels often enjoy increases in sales. Knowing how much inventory you have, how much you need for future sales and how to account for anomalies helps you plan for demand.

Good demand planning solidifies how much product to manufacture, how much raw materials to keep on hand, and how much to ship to different locations. Likewise, distributors must forecast customer demand.

All of that is easier said than done, but there are tools to help you sharpen your demand planning.

NetSuite’s native demand planning module is one of those tools. It helps manufacturers and distributors expertly predict required inventory based on historical demand and sales forecasts. Its features, functions and processes help manufacturers and distributors have the right materials available at the right time, and in the right place.

Demand planners and supply planners use NetSuite to keep a close eye on forecast vs. actual sales, relaying on a 360-degree dashboard and accurate reporting of KPIs.

Put simply, this tool offers the right balance of powerful functionality and ease-of-use to help you manage your inventory more efficiently, and in turn, improve inventory turnover and cash flow.

If you can’t tell, we’re huge fans of NetSuite and its demand planning module for manufacturers and distributors. Let’s go over some key aspects of demand planning that NetSuite handles like a pro.

Multi-Location Inventory

One of the key features that NetSuite delivers is the ability to easily define multiple inventory locations with real-time visibility. Locations can be organized hierarchically and for global businesses, the country can be defined. During the planning process, the system can be setup to automatically create transfer orders between locations where necessary.

Item Setup

One of the most critical areas of the planning process is defining the parameters that affect each item.

The settings that are found in the inventory management section of the item apply to the item as a whole unless they are overridden in the location sub-list. This defines the item as being available to demand planning, establishes an alternate source item (if you are trying to plan a new item with no sales history) and establishes which distribution network and category it might belong to if you are using DRP.

The location sub-list is where you’ll find additional planning parameters that affect how demand is evaluated or how the planned orders are generated.

These settings include:

- Safety stock level

- Lot sizing method

- Fixed lot size

- Supply planning periods

- Supply type

- Demand sources

- Entered and planned orders (uses expected ship date and if the item is part of an assembly, the demand for assembly will be included in the demand calculation for the item)

- Forecast and orders (quantity forecast over time plus quantities on orders and invoices entered)

- Forecast consumption

- The calculation is quantity forecast over time minus the quantity on sales orders and invoices entered

- Backward consumption is the number of days prior to the order date to consider

- Forward consumption is the number of days after the order date to consider whether an order falls within the consumption window

- Forecast from demand plan

- Demand and planning time fences

- Reschedule in/out days

- Manufacturing (note that new work orders can be generated by the demand planning engine)

- Do not generate

- Generate in planned firm status

- Generate in planned open status

- Generate in released status

The Demand Planning Process

Once the demand planning key fields have been populated on an item record, demand can be evaluated and presented in a number of different ways using the demand planning process.

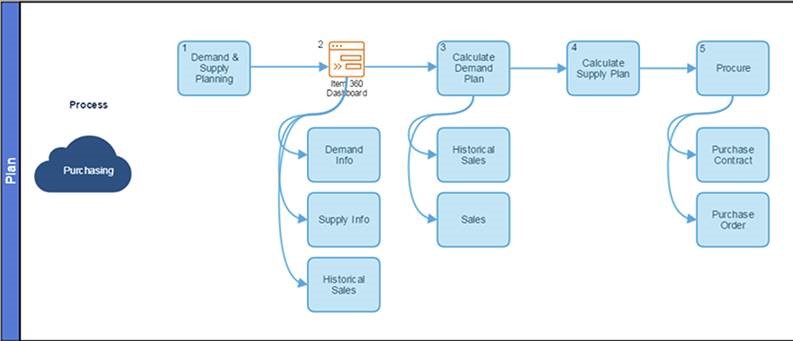

Here’s how that flow, represented by steps 1-3, looks in NetSuite.

NetSuite’s demand and supply planning flow

NetSuite’s menu structure is laid out in a way that shows the process to calculate demand, review the demand plans and edit where required, generate the supply plans, review and edit those plans, and finally generate planned purchase orders, transfer orders and work orders as desired.

Note that the system can be setup to generate actual transactions and skip the planned orders if desired.

Available Projection Methods

Linear regression – use previous demand to project future inventory based on the ordinary-least-square regression method

Moving average – use the moving average of historical demand to calculate the overall average stock level needed, and then project future stock levels using that overall average

Seasonal average – use previous demand to examine the seasonal trend of inventory flow, and then project a similar seasonal trend for future stock levels

Sales forecast – when using NetSuite for your sales operations, this option uses forward-looking sales forecast data such as opportunities, estimates, etc. to project inventory demand

Calculate Item’s Demand

NetSuite anticipates demand for you by analyzing historical, current and projected future sales.

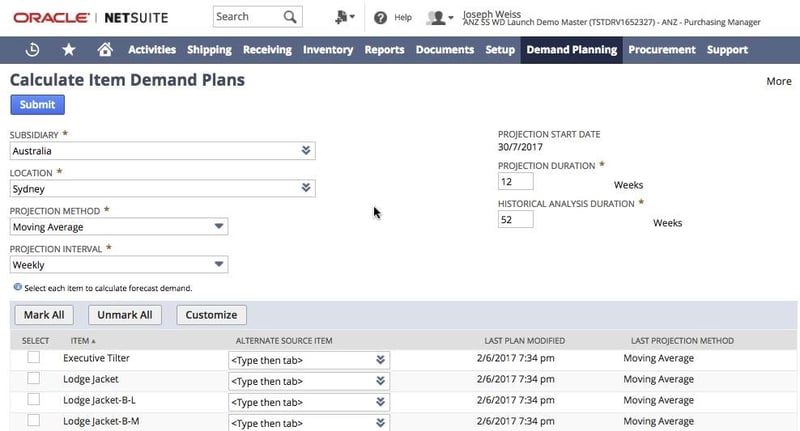

Simply select a projection method (the example below has moving average selected), projection interval, projection duration and historical analysis duration to calculate an item’s demand by subsidiary/location.

Your demand plan should consider sales orders, assemblies, work orders, transfer orders and intercompany transfers. Inventory adjustments are excluded from the process since they are typically used during inventory count inconsistencies. Again, if you are using the marketing and sales features in NetSuite’s CRM tool, outstanding opportunities and estimates as well as sales orders will be used. NetSuite provides filter options to customize the view of your results.

NetSuite can also use sales history of an alternative source item.

Example of item demand calculation

Supply Planning

Demand planning and supply planning go arm in arm in the manufacturing and distribution industry. They work symbiotically to ensure efficient product delivery and meet the financial goals of the business. Now that we’ve looked at demand planning, we’ll look closely at supply planning — which fulfills the demand plan — in our blog post, Supply Planning for Manufacturers and Distributors.

Key Benefits

In the meantime, let’s recap. NetSuite’s demand planning module helps you:

- Optimize inventory levels

- Increase turns

- Reduce costs with order consolidation

- Simplify the ordering process

- Handle workflow approvals

Need Help?

Looking to fine-tune and improve your demand planning? Contact us online or give us a call at 410.685.5512 for a demo or to talk through your inventory challenges.